|

个人信息Personal Information

教授

博士生导师

硕士生导师

教师拼音名称:zhanglin

电子邮箱:

入职时间:2023-06-15

所在单位:机电工程学院

职务:副主任

学历:研究生(博士)毕业

办公地点:长春工业大学主楼1462

性别:男

学位:博士学位

在职信息:在职

毕业院校:[美]俄亥俄州立大学

其他联系方式Other Contact Information

邮编 :

通讯/办公地址 :

邮箱 :

个人简介Personal Profile

张霖,男,工学博士,中共党员,教授,博士生导师,国家级高层次青年人才,吉林省高层次人才,吉林省高性能制造及检测国际科技合作重点实验室副主任,吉林省微纳与超精密制造重点实验室学术骨干。分别于2011年和2014年在吉林大学机械科学与工程学院获得工学学士与硕士学位(导师:赵宏伟教授),2015年获美国俄亥俄州立大学全额奖学金资助攻读博士学位(导师:Allen Yi教授),2020年受日本学术振兴会(JSPS)奖励资助,以JSPS外国人特别研究员身份在日本庆应义塾大学闫纪旺教授研究室开展研究工作,并于2022年度入选国家青年人才计划。2023年6月以教授/博士生导师身份入职长春工业大学机电工程学院。目前是日本精密工学会(JSPE)正会员,国际电气与电子工程师协会(IEEE)会员和美国光学学会(OSA)会员,同时也是20余种SCI期刊的审稿人。

主要从事超精密切削加工工艺与机理研究、精密玻璃模压工艺与装备开发及复杂光学元件设计与加工等方面的研究工作。研究内容涉及机械、光学、材料、力学、物理等多学科交叉领域。在CIRP Annals - Manufacturing Technology, Precision Engineering, Optics Letters, Optics Express等期刊发表SCI论文55篇,其中,作为第一/通讯作者发表SCI论文21篇,合著英文专著专章1章,以第一和第二发明人身份申请国家发明专利6项,2项发明专利得到产业转化。获得日本学术振兴会(Japan Society for the Promotion of Science)外国人特别研究员奖、俄亥俄州立大学校长奖学金(Presidential Fellowship)、香港政府奖学金(Hong Kong PhD Fellowship)、吉林省“十佳大学生”、吉林大学“十佳大学生”等奖励。

热诚欢迎对精密加工、材料测试、光学设计、微纳结构、控制工程等领域感兴趣的本科生、研究生和博士生加入研究团队。对表现优异的同学,可获得择优推荐读硕/博深造、国内/外交流培养机会。硕士名额相对充裕5-8人,博士每年招收2-3人!

English version: https://www.researchgate.net/profile/Lin-Zhang

指导优秀本科生取得的代表性成果:

1.创新与竞赛

[1].管宁汐等,2024年度长春工业大学“大学生创新创业训练”省级项目(优秀结题);

[2].冷冰聪等,2024年度长春工业大学“大学生创新创业训练”省级项目(优秀结题);

[3].冷冰聪等,2025年度长春工业大学“大学生创新创业训练”校级项目(立项);

[4].王威,管宁汐,2025年中国大学生机械工程创新创意大赛“精雕杯”毕业设计大赛东北赛区一等奖、三等奖

[5].王威,2025年中国大学生机械工程创新创意大赛“精雕杯”毕业设计大赛全国一等奖(银杯)

2.奖励与荣誉

[1].2024年长春工业大学优秀本科毕业设计论文(杨书宇);

[2].2025年长春工业大学优秀本科毕业设计论文(田飞宇,管宁汐);

指导优秀研究生取得的代表性成果:

1.创新与竞赛

[1].杨硕等,“挑战杯”吉林省大学生课外学术科技作品竞赛主体赛一等奖;

以下为实验室目前具备的主要研究与开发能力,热诚欢迎相关研究方向的专家、学者,科研单位及企业事业单位开展合作与交流!

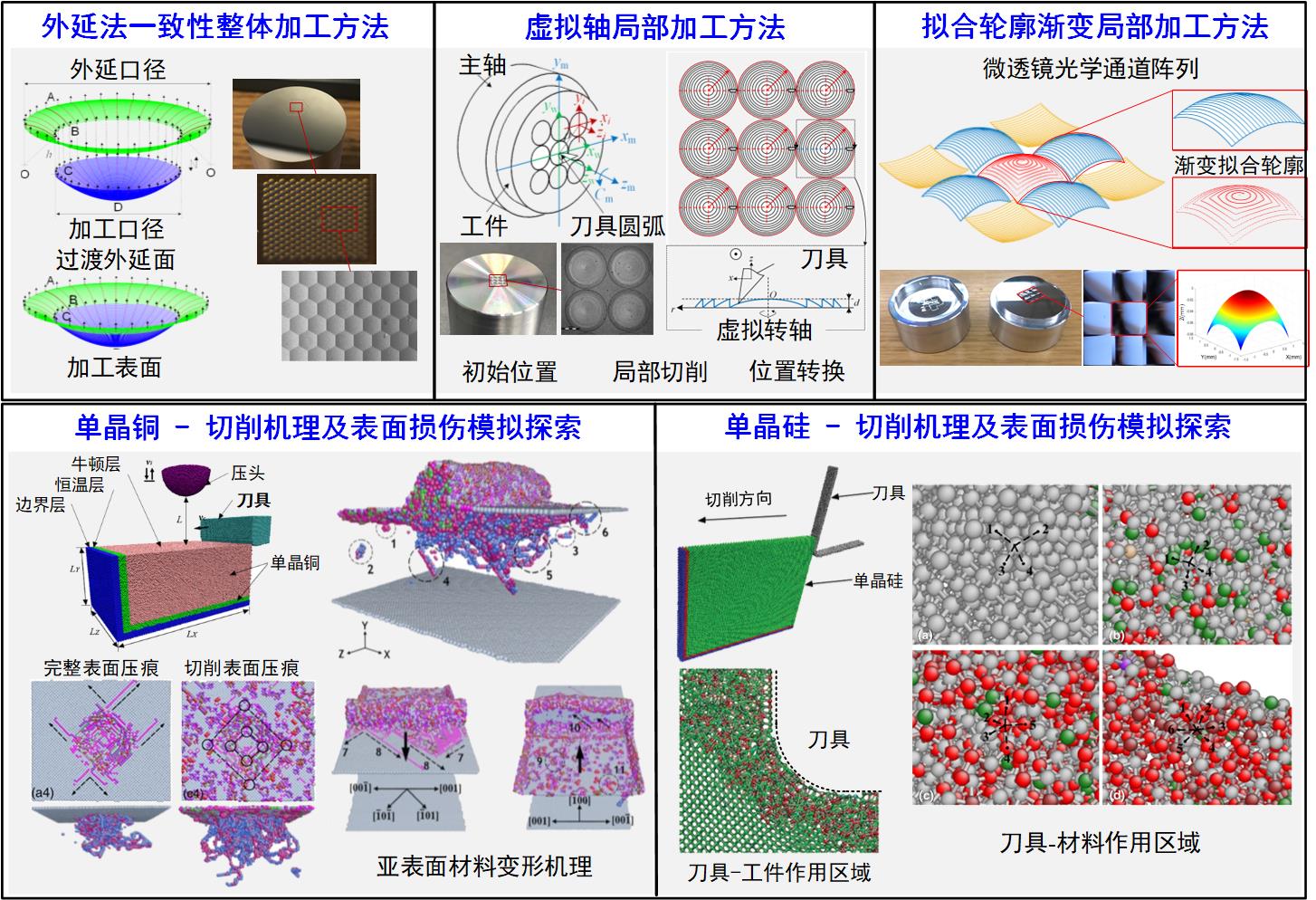

1、超精密切削加工工艺与切削机理研究

该方面代表性学术论文:

[1] Zhang L., Hashimoto T., Yan, J.* (2021) Machinability exploration for high-entropy alloy FeCrCoMnNi by ultrasonic vibration-assisted diamond turning. CIRP Annals - Manufacturing Technology, 70, 37-40.

[2] Wang C., Huang H.*, Zhang H.Y., Zhang L.*, Yan J.W. (2023) Laser repairing of FeCoCrNiV high-entropy alloy and its mechanical and cutting characteristics. Journal of Materials Processing Technology, 317, 118003.

[3] Zhang, L., Yi, A. Y, Yan, J.* (2022) Flexible fabrication of Fresnel micro-lens array by off-spindle-axis spiral diamond turning and precision glass molding. Precision Engineering, 74, 186-194.

[4] Zhang, L., Naples, N. J., Zhou W. C., & Yi, A. Y*. (2019) Fabrication of infrared hexagonal microlens array by novel diamond turning method and precision glass molding. Journal of Micromechanics and Microengineering, 29 (6).

[5] Zhang, L., Zhao, H. W., Dai, L., Yang, Y. H., Du, X. C., Tang, P. Y., & Zhang, L.* (2015) Molecular dynamics simulation of deformation accumulation in repeated nanometric cutting on single-crystal copper. RSC Advances, 5 (17), 12678-12685.

[6] Zhang, L., Huang, H., Zhao, H. W.*, Ma, Z. C., Yang, Y. H., & Hu, X. L. (2013) The evolution of machining-induced surface of single-crystal FCC copper via nanoindentation. Nanoscale Research Letters, 8 (1), 211.

[7] Zhang, L., Zhao, H. W.*, Yang, Y. H., Huang, H., Ma, Z. C., & Shao, M. K. (2014) Evaluation of repeated single-point diamond turning on the deformation behavior of monocrystalline silicon via molecular dynamic simulations. Applied Physics A, 116 (1), 141-150.

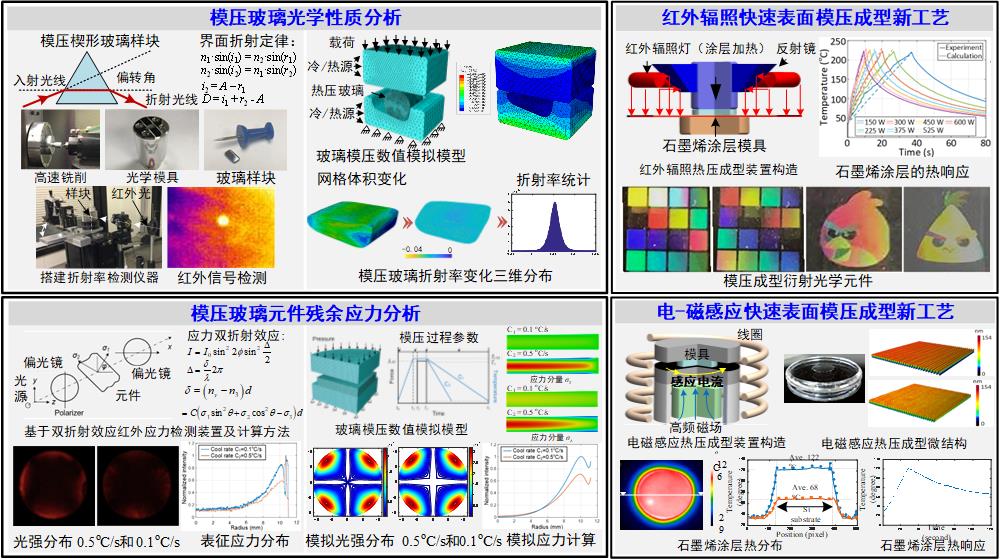

2、精密玻璃模压工艺与装备设计、优化、开发能力

该方面代表性学术论文:

[1] Zhang, L., Zhou W. C., & Yi, A. Y*. (2017) Rapid localized heating of graphene coating on a silicon mold by induction for precision molding of polymer optics. Optics Letters, 42 (7), 1369-1372.

[2] Zhang, L.*, Zolfaghari, A., Zhou, W. C., Shu, Y., Yi, A. Y. (2022) Flexible metallic mold based precision compression molding for replication of micro-optical components onto non-planar surfaces. Precision Engineering, 76, 149-159.

[3] Zhang, L.*, Yan, J. (2022) Study on nano-graphitic carbon coating on Si mold insert for precision glass molding. Surface and Coatings Technology, 128893.

[4] Zhang, L.*, Yi, A. Y. (2021) Investigation of novel mid-infrared rapid heating of carbide-bonded graphene coating and its applications on precision optical molding. Optics Express, 29, 30761-30771.

[5] Zhang, L.*, & Yi, A. Y. (2020) Manufacturing of a microlens array mold by a two-step method combining microindentation and precision polishing. Applied Optics, 59 (23), 6945-6952.

[6] Zhang, L., Zhou W. C., & Yi, A. Y*. (2018) Investigation of thermoforming mechanism and optical properties’ change of chalcogenide glass in precision glass molding. Applied Optics, 57 (22), 6358-6368.

[7] Zhang, L., Zhou W. C., Naples, N. J., & Yi, A. Y*. (2018) Investigation of index change in compression molding of As40Se50S10 chalcogenide glass. Applied Optics, 57 (15), 4245-4252.

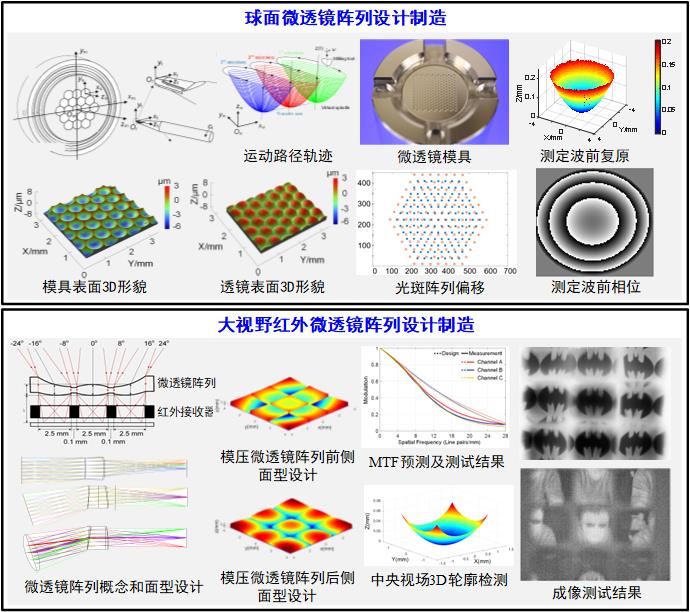

3、复杂光学元件设计、加工与测试能力

该方面代表性学术论文:

[1] Zhang, L., Zhou, L., Zhou, W. C., Zhang, S. Q., & Yi, A. Y*. (2020) Design, fabrication and testing of a compact large-field-of-view infrared compound eye imaging system by precision glass molding. Precision Engineering, 66, 87-98.

[2] Zhang, L., Zhou W. C., Naples, N. J., & Yi, A. Y*. (2018) Fabrication of an infrared Shack–Hartmann sensor by combining high-speed single-point diamond milling and precision compression molding processes. Applied Optics, 57 (13), 3598-3605.

[3] Zhong, Y., Du, R.X., Zhang, L.*, Yi, A. Y. (2020) Structural colorization of surfaces with microstructures replicated by non-isothermal precision glass molding, Journal of Micro- and Nano-Manufacturing, 8, 041003.

[4] Zhou W. C., Zhang, L., & Yi, A. Y*. (2018) Design and Fabrication of a Compound-eye System using Precision Molded Chalcogenide Glass Freeform Microlens Arrays. Optik - International Journal for Light and Electron Optics, 171, 294-303.

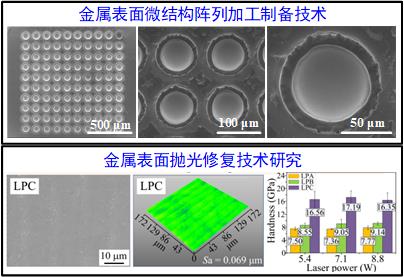

4、材料表面激光微结构制造与功能化的能力(合作研究)

该方面代表性学术论文:

[1] Huang, H., Qian, Y., Zhang, L.*, Jiang, M., & Yan, J. (2022) A novel method for fabricating micro-dimple arrays with good surface quality on metallic glass substrate by combining laser irradiation and mechanical polishing under wax sealing, Journal of Manufacturing Processes, 79, 911-923.

[2] Huang, H., Hong, J., Qian, Y., Wang, C., Zhang, Z., & Zhang, L*. (2022) Nanosecond laser polishing of laser nitrided Zr-based metallic glass surface, The International Journal of Advanced Manufacturing Technology, 121, 4099-4113.

[3] Huang, H., Qian, Y., Zhang, L.*, Jiang, M., & Yan, J. (2022) A novel method for fabricating micro-dimple arrays with good surface quality on metallic glass substrate by combining laser irradiation and mechanical polishing under wax sealing. Journal of Manufacturing Processes, 79, 911-923.

[4] Huang, H., Hong, J., Qian, Y., Wang, C., Zhang, Z., & Zhang, L*. (2022) Nanosecond laser polishing of laser nitrided Zr-based metallic glass surface. The International Journal of Advanced Manufacturing Technology, 121, 4099-4113.

[5] Zhang, H., Qian, Y., Zhang, L., Zhang, D., Liu, H., & Huang, H*. (2021) Surface coloration of Zr-based metallic glass by nanosecond pulsed laser irradiation in ambient atmosphere. Materials Letters, 304, 130721.

[6] Zhang, L., & Huang., H*. (2019) Micro machining of bulk metallic glasses: a review. The International Journal of Advanced Manufacturing Technology, 100 (1-4), 637–661.

5、Laser扫描系统的高精度与智能化数据处理研究(合作研究)

该方面代表性学术论文:

[1] Ji X., Yang B., Wei Z., Wang M., Tang Q., Xu W., Wang Y., Zhang J., Zhang L. (2024). Benthic habitat sediments mapping in coral reef area using amalgamation of multi-source and multi-modal remote sensing data[J]. Remote Sensing of Environment, 2024,304:114032.

[2] Ji, X., Dong, Z., Wei, Z., Wang, M., Xu, W., & Zhang, L.* (2024). An Adaptive Local Joint-Weighted Method for Continuous Stripping Intensity Correction of Airborne Bathymetric LiDAR. IEEE Transactions on Geoscience and Remote Sensing, 62, 1-12.

[3] Ji, X., Dong, Z., Zhang, L., Wang, M., Ma, Y., Zhang, J. (2023). Waveform classification and index sharing based-effective intensity data extraction of airborne laser bathymetry. International Journal of Applied Earth Observation and Geoinformation, 124, 103503.

团队名称:先进光学与智能制造研究室(请关注团队公众号,及时留意团队最新动态)

加入我们

硕士研究生 博士研究生 研究助理 师资博士后 (详情见“招生信息”栏)

欢迎各位有志青年加盟

有意应聘者请将详细简历发送至以下邮箱:

张 霖:zhanglin@ccut.edu.cn

工作地点

吉林省长春市延安大街2055号 长春工业大学

团队成员Research Group

团队名称:先进光学与智能制造研究室

团队介绍:长春工业大学先进光学制造研究室,隶属于机电工程学院,团队由林洁琼教授、张霖教授为核心成员,该研究室主要从事超精密切削加工、精密玻璃模压装备及技术、智能制造及检测技术等方面的研究工作。团队先后承担国家级、省部级重点项目3项,授权国家发明专利10余项,发表论文50余篇。目前团队具有一流的超精密加工试验条件及设备,与国内外一流高校建立了良好的交流合作关系,欢迎有志同学加入团队。